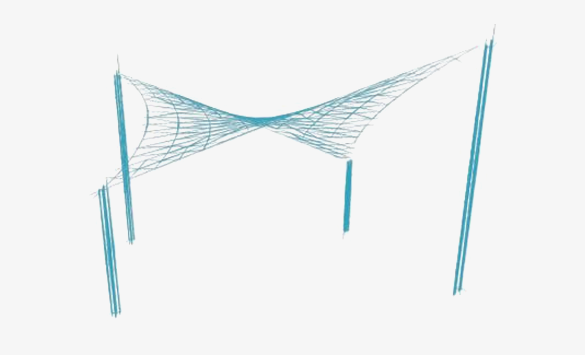

Quality Is The Difference

Its often very difficult to compare shade sail quotes, as your not often comparing like for like. There needs to be consistency across all aspects of planning and manufacturing a shade sail in order to produce a quality product that will not only look good, but last the test of time. ONE Shade manufacture the shade sails to a very high quality using only tried and tested material and install methods.